Current sustainable packaging seems to be failing the structural test, driving up waste and shipping costs. This post dives deep to decode the Biomimicry Chiral Packaging inspired by the Beetle’s Chiral Layering System, which is a natural, ultra light armor. This system is used to engineer high-strength, mono-material composites. We propose that achieving zero-waste packaging is not just a material choice!

Why Bio-Packaging Must Mimic the Beetle

The dialogue is in motion! We’re excited to share this exclusive clip discussing the full analysis of our Nature’s Composite blog post. This conversation confirms the urgent need to address fragility in sustainable packaging using the Mimétique Code.

Listen now to hear this discussion by two AI-minds that is shaping the next wave of bio-innovation!

Conceptual Exploration Disclaimer: This strategic analysis in this blog post and associated media is a conceptual model, offered for thoughtful discussion as part of our platform for shared learning. It is not certified professional advice. Any application of these principles is undertaken solely at the user’s risk, as detailed in our full Terms of Service.

I. The Crisis: The Hidden Cost of Fragility

The luxury material paradox becomes a strategic imperative.

Here’s the dilemma: Brands can no longer ignore the push for sustainability, but that push is constrained by a terrible choice. On one side, you have traditional animal leather which offers unmatched quality, but a huge ethical and environmental price tag. On the other side, the first wave of sustainable bio-materials just isn’t there.

This compromise directly erodes brand value and consumer trust.

This is not merely a sourcing challenge; it is fundamentally a Design and Process Engineering failure deeply rooted in outdated industrial models. While the immense potential of the global Mycelium market is clear, its industrial promise is undermined by a single bottleneck: unpredictable quality control during the post-growth phase. This drives cost, compromises aesthetics, and stalls market adoption at scale.

The inconsistencies arise from variations in mycelial growth, substrate composition, environmental factors during cultivation, and processing techniques. This leads to significant batch-to-batch variability. Such unpredictability results in undesirable outcomes, including inconsistent thickness, strength, texture, color absorption, and material integrity. This lack of reliability has profound commercial consequences. It drives up production costs due to higher waste rates and the need for extensive sorting and grading. It also compromises the aesthetic and performance luxury brands demand, ultimately stalling market adoption at scale.

Therefore, to truly unlock the transformative potential of mycelium and overcome the Luxury Material Paradox, we must fundamentally shift the design mandate. Our focus must move beyond simply “growing a material” and evolve towards “engineering the consistency of the growth process” itself. This necessitates a holistic, systems-level approach. We must integrate advanced biotechnology, precision engineering, data analytics, and rigorous quality assurance protocols at every stage of the mycelium’s lifecycle, from spore inoculation to final material finishing.

II. The Mimétique Code: The Chiral Layering System

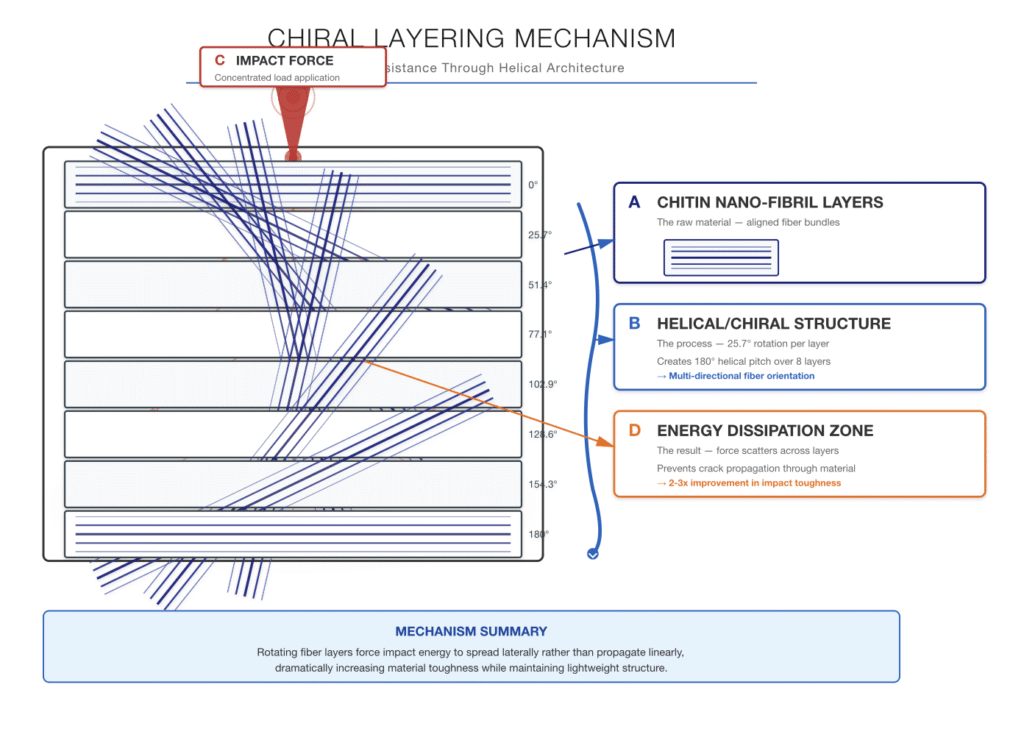

Allow me to introduce you to a truly remarkable feat of natural engineering: the beetle shell’s secret, the Chiral Composite. This isn’t just a hard outer casing; it’s a meticulously designed structure. It grants the insect immense toughness and unparalleled impact resistance without relying on heavy, brittle minerals. Instead, its strength comes from layered, twisted nano-fibrils of chitin, a natural, fibrous polymer.

Imagine a microscopic spiral staircase or, more aptly, a natural form of plywood on a nanoscale. Each successive layer of chitin fibrils is precisely rotated at a slight angle relative to the layer beneath it. This continuous, gradual twist creates a helical arrangement, a chiral structure, which is key to its extraordinary properties. When impact forces strike the beetle’s shell, this layered, twisted configuration acts as an efficient shock absorber. The energy from the impact isn’t concentrated in a single plane. Instead, it is distributed and dissipated across multiple layers and through the twisting architecture. This “plywood” effect prevents cracks from propagating easily, making the shell resistant to shattering and penetration.

Nature’s Smart Armor

This ingenious structure is naturally anisotropic. What does that mean? Simply that its strength isn’t the same everywhere. It changes depending on the angle of the force. But this isn’t a flaw, it is a brilliant design feature.

For instance, the beetle can optimize its shell for maximum resilience exactly where it needs protection most. This could be in areas prone to stress or impact. At the same time, it can minimize mass and maintain flexibility in calmer spots.

This perfect balance of targeted strength and overall lightness is amazing. It shows the incredible efficiency of the chiral composite. It’s what allows the beetle to thrive everywhere, even in the toughest environments.

III. The new manufacturing mandate

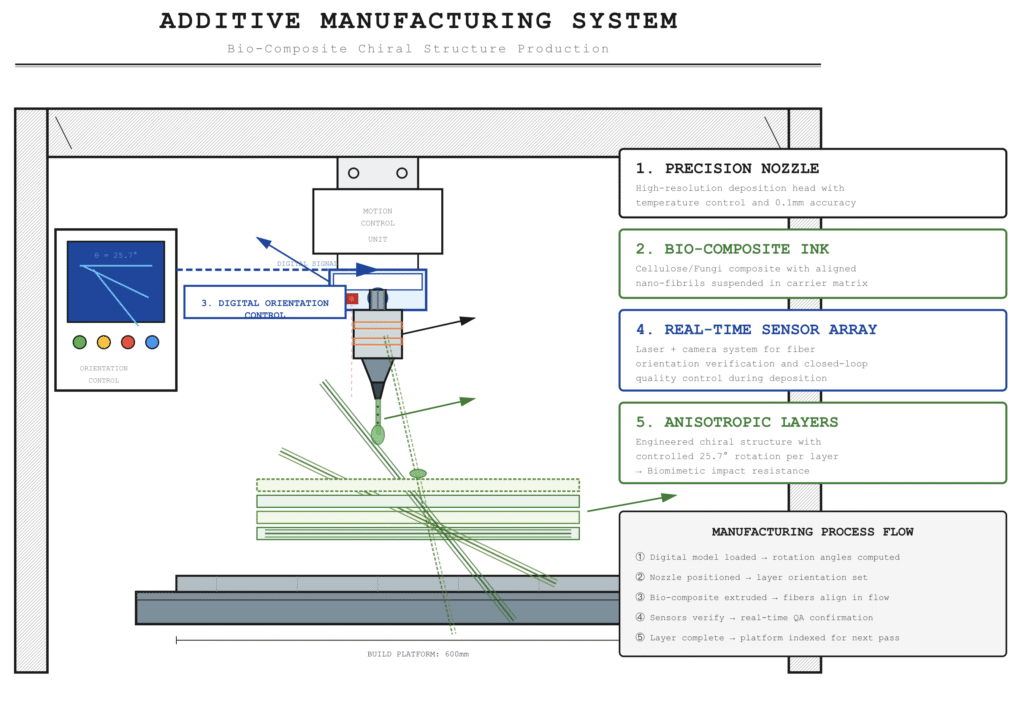

The exciting potential of Chiral Layering opens new doors for material science. In fact, we could potentially translate this into a robust industrial process.

Imagine leveraging 3D printing to gain control. This control dictates the layer orientation of biodegradable materials, like cellulose or fungi-based bio-composites. This precision then could unlock a new era of sustainable, high-performance materials.

Precision Structural Engineering

This paradigm shift elevates bio-packaging. The well known pulp forming process, does recycle paper and water to create pulp. The pulp is then molded into custom shapes and dried to form protective packaging. Here, we could move past simple pulp forming and into precision structural engineering by learning from the Chiral Layering.

By digitally dictating how natural fibers align, we can craft ultra-light packaging forms. These forms incorporate sophisticated, engineered impact zones. These zones maximize protection, absorbing and dissipating forces far more effectively than traditional methods. This cuts product damage during transit and dramatically reduces material usage.

The result is better for everyone. We can customize the mechanical properties of each layer for different industries, from electronics to consumer goods. This innovative approach provides both performance and environmental responsibility.

IV. Why this innovation could meet our planet goals!

This theory delivers a potential Return on Investment through three core advantages:

- We dramatically reduce the material mass needed for packaging. Less material means far lower raw material expenses. It also means lighter shipments, cutting transport costs. These efficiencies instantly boost our overall (theoretical) profitability.

- This could guarantee high-strength protection for even your most valuable goods. It could then eliminate customer complaints about breakage in transit. Quite the safeguard for your brand’s reputation and a way to build customer satisfaction and loyalty!

- We could design a mono-material, fully compostable composite. This groundbreaking material could directly replace complex and also unrecyclable plastics. You could then be reducing your environmental footprint and immediately appeal to your amazing eco-conscious consumers. This is the definition of a circular solution.

The Mimétique Code in Motion: Watch our deep dive into the Nature’s Composite strategic brief, now visualized by Notebook LM.

Leave a Reply